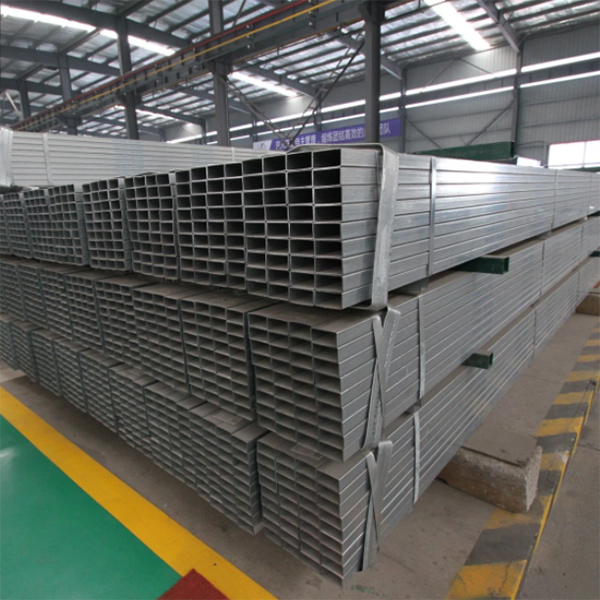

ASTM A500 lisekoere tsa tšepe tsa feme ea feme ea feme ea feme ea thepa

A500 Carbon Steel Square Tubing, phala e kholo ea bophara ba lisekoere tsa tšepe, phala ea tšepe e se nang sekoere, phala e tlase ea tšepe ea lisekoere, phala ea tšepe ea 135 * 135 * 10 lisekoere tsa tšepe, phala ea tora ea square ea tšepe, Q345B phala ea tšepe e tlase ea alloy, 20 # seamless square steel. phala

A500 Carbon Steel Square Tubing, joalo ka ha lebitso le bolela, ke sebopeho sa lisekoere tsa tube, mefuta e mengata ea thepa e ka etsa 'mele oa square tube, o bohareng ba eona, o ka sebelisa eng, o sebelisoa hokae, boholo ba phala ea lisekoere ho ea tšepe. phaephe bakeng sa bongata, haholo bakeng sa peipi ea sebopeho sa lisekoere, mokhabiso oa square pipe, moaho oa lisekoere pipe joalo-joalo.

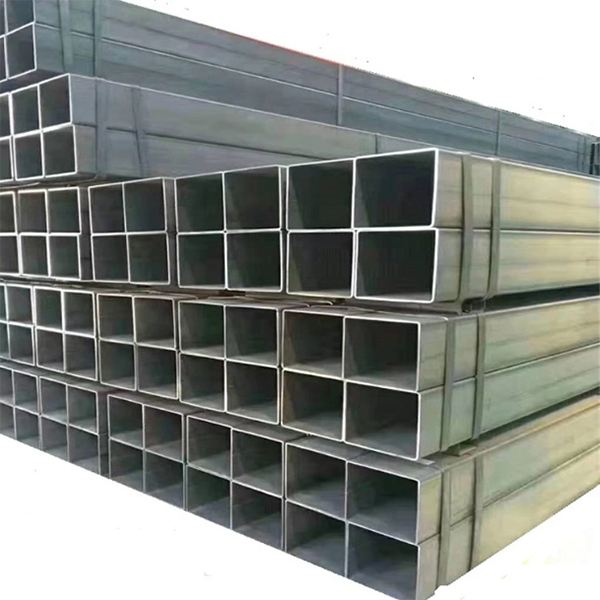

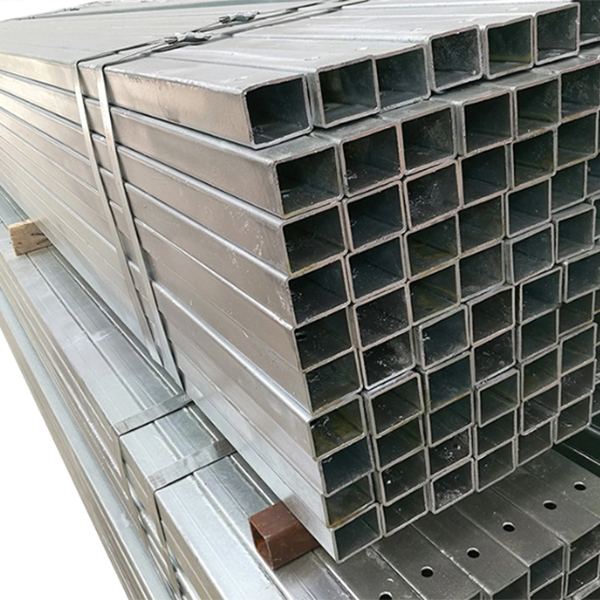

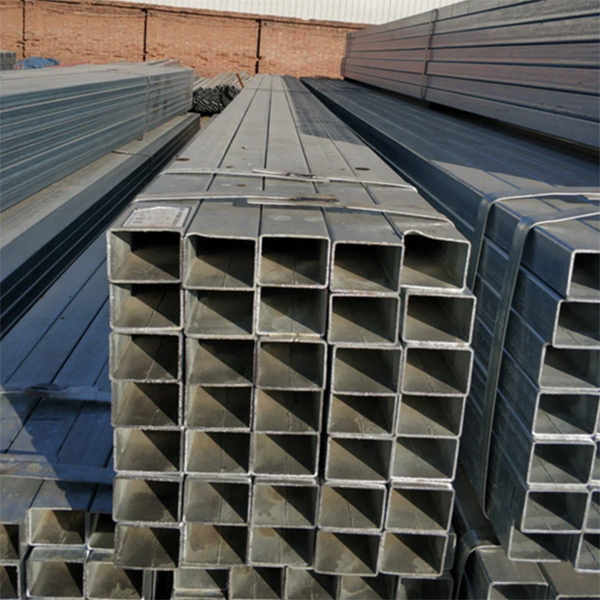

Pipe ea lisekoere ke lebitso la pipe ea lisekoere, ke hore, pipe ea tšepe e nang le bolelele bo lekanang ka mahlakoreng ka bobeli.E entsoe ka tšepe ea hlobolisa ka mor'a ho sebetsa le ho roala.Ka kakaretso, lesela lena lea phuthoa, lea lekanngoa, le thijoa le ho chesetsoa ka har'a tube e chitja, e phuthoang ka har'a tube e sekoere ebe e khaola bolelele bo hlokahalang.Hangata lithupa tse 50 pakete ka 'ngoe.

Classification Le Tshebetso

A500 Carbon Steel Square Tubing e se nang seam e arotsoe ka seamless le weld, seamless square pipe e entsoe ka seamless round tube extrusion.Pipe ea tšepe ea lisekoere, phala e teteaneng ea lisekoere tsa tšepe, phala e kholo ea bophara ba lisekoere tsa tšepe, phala e se nang sekoli ea tšepe, phala e tlaase ea tšepe e tlaase, 135 * 135 * 10 phala ea tšepe ea lisekoere, phala ea tora ea crane square steel pipe, Q345B low alloy square steel pipe, 20 # phala ea tšepe e se nang sekoli

1. Tlhahlobo ea index ea ts'ebetso ea tube ea tšepe ea lisekoere - polasetiki

Plasticity e bolela bokhoni ba lisebelisoa tsa tšepe ho hlahisa deformation ea polasetiki (deformation e sa feleng) ntle le tšenyo tlas'a mojaro.

2. Tlhahlobo ea index ea ts'ebetso ea tube ea tšepe ea lisekoere - boima

Ho thatafala ho lekanya hore na tšepe e thata kapa e bonolo hakae.Hona joale, mokhoa o atisang ho sebelisoa ho fumana hore na ho thata hakae tlhahiso ke mokhoa oa ho thatafala oa indenter, e leng ho sebelisa sebopeho se itseng sa geometri sa hlooho ea indenter tlas'a mojaro o itseng holim'a lisebelisoa tsa tšepe tse lekiloeng, ho latela tekanyo ea indenter ho fumana boleng ba boima ba yona.

Mekhoa e sebelisoang hangata ke Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) le Vickers hardness (HV) le mekhoa e meng.

3. Tlhahlobo ea index ea ts'ebetso ea tube ea tšepe ea lisekoere - mokhathala

Matla, polasetiki le boima bo boletsoeng ka holimo ke matšoao a lisebelisoa tsa tšepe tse tlas'a static loading.Ha e le hantle, likarolo tse ngata tsa mochine li sebetsa tlas'a meroalo ea cyclic, 'me mokhathala o ka hlaha tlas'a maemo ana.

4. Tlhahlobo ea index ea ts'ebetso ea pipe ea tšepe ea lisekoere - boima ba phello

Mojaro o sebetsanang le likarolo ka lebelo le phahameng o bitsoa " impact load", 'me bokhoni ba tšepe ba ho hanela tšenyo e tlas'a boima bo bitsoa ho tiea ha tšusumetso.

5. Tlhahlobo ea index ea ts'ebetso ea square steel tube - matla a lisekoere tsa tšepe, tube e teteaneng ea lisekoere tsa tšepe, tube e kholo ea lisekoere tsa tšepe, tube ea tšepe e se nang sekoere, tube e tlase ea tšepe, 135 * 135 * 10 square steel tube, tower crane square. tube tube, Q345B low alloy square steel tube, 20 # seamless square steel tube

Matla ke bokhoni ba thepa ea tšepe ho hanela ho hloleha (deformation e feteletseng ea polasetiki kapa fracture) tlas'a static loading.Ka lebaka la mokhoa oa ho jarisa ka mokhoa oa ho otlolla, ho hatella, ho koba, ho kuta, kahoo matla a boetse a arotsoe ka matla a tsitsitseng, matla a khatello, matla a ho koba, matla a ho kuta joalo-joalo.Hangata ho na le khokahano e itseng lipakeng tsa matla a fapaneng, 'me matla a ho tiea hangata a sebelisoa e le sesupa sa motheo sa matla.

Qetello ea sebopeho:pheletso e oblique, pheletso e bataletseng, e nyamele kapa eketsa sekoaelo sa polasetiki ho sireletsa lipheletsong ho latela litlhoko tsa bareki.

Theknoloji:ho bidika ho chesang, ho thetheha ho batang

Sesebelisoa sa A500 sa Carbon Steel Square Tubing

1. Likopo tsa meralo, kaho ea indasteri le ea bolulo

2. Fense ea terata / terata / li-bollards / foreimi ea bethe

3. Khase

4. Ka mokhoa oa ho fafatsa mollo / phepelo ea metsi

5. Lisebelisoa tsa lipapali / palo e khanyang / lebone la lebone

6. Temo/greenhouse

Tlhaloso

| Ho hanyetsa welding | |||||||||

| ntho | Boholo ba metsoako ea lik'hemik'hale % | ntho | Boitšoaro ba mechine | ||||||

| tshepe | C % | Manganese % | % | % | silicon% | tshepe | Yield point Mpa | Matla a tenneng Mpa | Elongation |

| Sehlopha sa A | 0.25 | 0.95 | 0.045 | 0.05 | -- | Sehlopha sa A | 205 (metsotso) | 330 (metsotso) | 26-30 |

| Sehlopha sa B | 0.3 | 1.2 | 0.045 | 0.05 | -- | Sehlopha sa B | 240 (metsotso) | 415 (metsotso) | 21-26 |

| Maemo a Boleng: Tlhaloso e Tloaelehileng ea ASTM A53 ASTM A500 bakeng sa Pipe, Black and Hot Dip, Galvanized, Welded, and Seamless Tubing | |||||||||

Sebopeho sa Lik'hemik'hale

| Litlhoko tsa lik'hemik'hale | Boitšoaro ba mechine | Tube ea sebopeho se ikhethileng | |||||||||

| Element | sebetsa.% | Sehlopha sa A | Sehlopha sa B | Sehlopha sa C | Sehlopha sa D | ||||||

| Sehlopha sa A, B, D | Sehlopha sa C | Matla a thata, min, | psi | 45000 | 58000 | 62000 | 58000 | ||||

| Mocheso Tlhahlobo | Sehlahisoa Tlhahlobo | Mocheso Tlhahlobo | Sehlahisoa Tlhahlobo | MPa | 310 | 400 | 427 | 400 | |||

| Kotulo Matla, Min, | psi | 33000 | 42000 | 46000 | 36000 | ||||||

| C, boholo | 0.26 | 0.30 | 0.23 | 0.27 | MPa | 228 | 290 | 317 | 250 | ||

| Manganese, max | … | … | 1.35 | 1.40 | 2" bolelele.(50.8mm), mets% | 25 | mashome a mabeli a metso e meraro | mashome a mabeli a motso o le mong | mashome a mabeli a metso e meraro | ||

| P, max | 0.035 | 0.045 | 0.035 | 0.045 | Maemo a Boleng: Tlhaloso e Tloaelehileng ea ASTM A500 bakeng sa Pipe ea Sebopeho sa tšepe e pota-potileng le e bōpehileng joaloka Cold-Form le e se nang Seamless Carbon Steel Structural Pipe | ||||||

| e nyane, e kgolo | 0.035 | 0.045 | 0.035 | 0.045 | |||||||

| Koporo, (ha e hlalositsoe) min. | 0.20 | 0.18 | 0.20 | 0.18 | |||||||

Pontšo ea Sehlahisoa