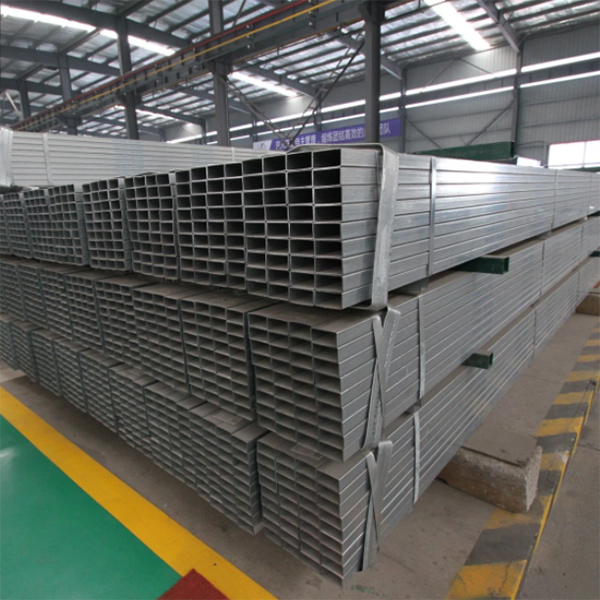

ASTM A53 Square Tubing bakeng sa lits'ebetso tsa meralo

Pipe ea ASTM A53 Square E SEBELISA kaho, tlhahiso ea mechini, merero ea kaho ea tšepe, kaho ea likepe, li-stents tsa matla a letsatsi, boenjiniere ba sebopeho sa tšepe, lihlahisoa tsa liphaephe tsa matla a motlakase, metjhini ea temo le lik'hemik'hale, lebota la likhalase tsa khalase, chassis ea koloi, boema-fofane, moaho oa boiler. , liporo tsa litsela tse kholo, kaho ea matlo, sekepe sa khatello, litanka tsa polokelo ea oli, Marokho, lisebelisoa tsa seteishene sa motlakase, Mechini ea ho phahamisa le ea lipalangoang le meaho e meng e phahameng ea tjheseletsa.

Classification Of ASTM A53 Square Pipe Production Process

Pipe ea ASTM A53 ea lisekoere ho latela ts'ebetso ea tlhahiso: tube e chesang e kentsoeng e se nang seamless, tube e batang e se nang sekoti, e petelletsa seamless square tube, welded square tube.

Li-welding square tubes li arotsoe ka:

(a) arc welding square tubes, resistance welding square tubes (high frequency, low frequency), Gas welding square pipe, welding square welding pipe

(b) Ho ea ka weld, e arotsoe ka e 'ngoe - seam e otlolohileng welded square pipe le spiral welded square pipe.

Tlhaloso ea lintho tse bonahalang tsa Astm A53 Square Pipe

Sekwere tube ho latela thepa: plain carbon steel square tube, low alloy square tube.Carbon tšepe e arotsoe ka: Q195, Q215, Q235, SS400, 20 # tšepe, 45 # tšepe;Tšepe ea alloy e tlase e arotsoe ka Q345, 16Mn, Q390, ST52-3, joalo-joalo.

Sehlopha se Tloaelehileng sa Tlhahiso ea Astm A53 Square Pipe

Square tube ho latela maemo a tlhahiso: gb square tube, Japanese standard square tube, British system square tube, American standard square tube, European standard square tube, non the square tube.

Sebopeho sa Sebopeho sa Karolo ea Square Tube

Liphaephe tse sekwere li arotsoe ho ea ka sebopeho sa karolo:

(1) karolo e bonolo phala ea lisekoere - - phala ea lisekoere tsa lisekoere, phaephe ea lisekoere tsa lisekoere

(2) karolo e rarahaneng ea square tube - palesa e bopehileng joaloka square tube, tube e bulehileng ea lisekoere, tube e entsoeng ka lisekoere, tube e entsoeng ka lisekoere

Tlhaloso

Kereiti ea tšepe:A53 Gr.A, Gr B, A106 GR.A GR.B A333 GR1 GR3 GR6 S355JR S355JO 355J2

Kantle DiameterTlhaloso: 20X20-600X600

Botenya ba Lebota:1mm-40mm

Bolelele:Random Length, SRL, DRL(4-14M)

QETA:morero oa fella

Ho paka:Li-bundle tse tlotsoeng ka oli e bobebe

Sebopeho sa Lik'hemik'hale

| Likarolo tsa Lik'hemik'hale tsa ASTM A53 / A106 le Thepa ea Machanical | |||||||||||||

| Standard | Kereiti ea tšepe | Likaroloana tsa Lik'hemik'hale | Thepa ea Machanical | ||||||||||

| C | Mn | P | S | Cu | Ni | Cr | Mo | V | Tensile Strength (Mpa) | Yield Strength(Mpa) | Elongation (Mpa) | ||

| ASTM A53 | A | ≤0.25 | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

| Standard | Kereiti ea tšepe | Likaroloana tsa Lik'hemik'hale | Thepa ea Machanical | ||||||||||

| C | Si | Mn | P | S | Ke, Ke | Cr | Mo | V | Tensile Strength (Mpa) | Yield Strength(Mpa) | Elongation (Mpa) | ||

| ASTM A106 | B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ≥485 | ≥275 | ≥30 | |

LBH

1.Ke mosebetsi oa mofuta ofe oo k'hamphani ea hau e o etsang?

Khamphani ea rona ke moetsi oa litsebi.

Haholo-holo re hlahisa letlapa la tšepe / phala / khola / litšepe tse pota-potileng, hammoho le poleiti e entsoeng ka masenke / phala / khola / terata ea lead / lakane e entsoeng ka masenke, jj.

2.Na u fana ka mehlala ea mahala?

Ee, re ka fana ka sampole ea mahala bakeng sa tlhahlobo, moreki o lokela ho jara litšenyehelo tsohle tsa thomello.

3.Na nako ea hau ea ho fana ka nako e kae?

Ka kakaretso ke matsatsi a 3-7 haeba thepa e le teng kapa ke matsatsi a 7-15 haeba thepa e le sieo, ho latela bongata.

4.Re ka tiisa boleng joang?

Kamehla sampole ea pele ho tlhahiso pele ho tlhahiso ea bongata;Kamehla Tlhahlobo ea ho qetela pele e romelloa.Mme re ka boela ra amohela tlhahlobo ea motho oa boraro le ho behelloa ka thoko.

5.Hobaneng u lokela ho reka ho rona eseng ho bafani ba bang?

Lihlahisoa tse fapaneng, phepelo e tobileng e tsoang ho moetsi.

Pontšo ea Sehlahisoa