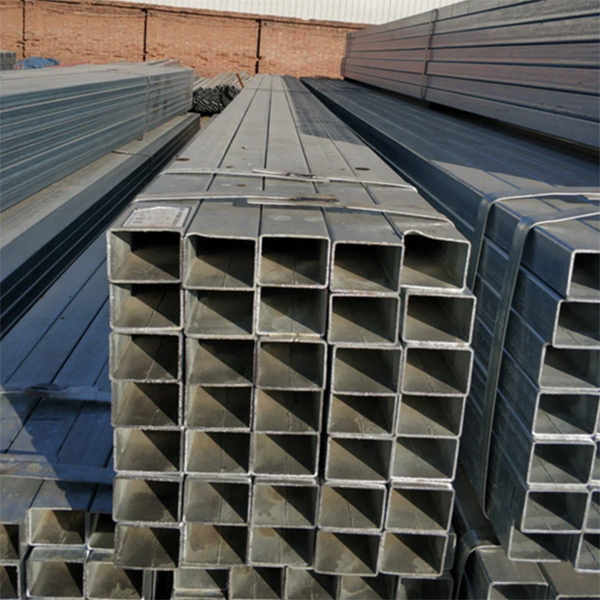

Square Structural Steel Tubing

Square structural tšepe tubing, eo hape e tsejoang e le phala e cheselitsoeng, e entsoe ka poleiti ea tšepe kapa hlobolisa ka mor'a ho qhekella ho etsa phala e cheselitsoeng ea lisekoere.

Square structural steel tubing, thepa e sebediswang ka tlwaelo ke: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00Ni10Cr18b 19 Ni10Cr1, 1Ni10Cr19

Welded tšepe e sa hloekang phala bakeng sa mokhabiso (GB/T 18705-2002), welded phala tšepe e sa hloekang bakeng sa mokhabiso moaho (JG/T 3030-1995), welded tšepe phala bakeng sa lipalangoang tlaase-khatello mokelikeli (GB/T 3091-2001), le phala ea tšepe e cheselitsoeng bakeng sa phapanyetsano ea mocheso (YB4103-2000).

Mokhoa oa Tlhahiso

Square structural tšepe tubing, likheo tse Narrow li ka sebelisoa ho hlahisa liphaephe tse cheselitsoeng tse nang le bophara bo boholo, 'me likheo tsa bophara bo lekanang li ka sebelisoa ho hlahisa liphaephe tse cheselitsoeng tse nang le bophara bo fapaneng.Empa ha ho bapisoa le bolelele bo lekanang ba phala e otlolohileng ea seam square, bolelele ba weld bo eketseha ka 30 ~ 100%, mme lebelo la tlhahiso le tlase.

E kholo kapa e teteaneng ka bophara ba lisekoere tsa meralo ea tšepe, Ka kakaretso e entsoe ka billet ea tšepe ka ho toba, le phala e nyenyane e cheselitsoeng e tšesaane phala e tšesaane e lokelang ho kenngoa ka ho toba ka lebanta la tšepe.Ka mor'a ho bentša ha bonolo, terata e se e loketse.Ka hona, phala e nyane e cheselitsoeng hangata e sebelisa tjheseletsa e otlolohileng ea seam, phala e kholo e cheselitsoeng hangata e sebelisa spiral welding.

Shape The Performance

square structural steel tubing, Ke lebitso la phala e sekwere, e leng phala e bolelele bo lekanang ka mahlakoreng ka bobedi.E entsoe ka tšepe ea hlobolisa ka tharollo ea ts'ebetso le ho roala.Ka tloaelo, hlobolisa ha e sa phutholoha, e bataletse, e crimped, e tšeloa ka har'a tube e chitja, ebe e phuthoa ke tube e chitja Q215 e entsoeng ka lisekoere ebe e khaola bolelele ba tlhoko.Nomoro e tloaelehileng ke 50 pakete ka 'ngoe.Matla a bolela mosebetsi oa ho hanyetsa tšenyo (deformation e nepahetseng ea polasetiki kapa fracture) ea Q215 welded square pipe data tlas'a mojaro o tsitsitseng.Hobane mojaro oa mofuta oa tensile, contraction, matsoelintsoeke, kuta le litsela tse ling, hobane matla a boetse a arotsoe ka tensile matla, compressive matla, kobang matla, ho kuta matla joalo-joalo.Mefuta eohle ea matla hangata e na le kamano e tobileng, tšebeliso e tloaelehileng ea matla a tsitsitseng e le nale ea bohlokoa ka ho fetisisa ea matla.Matla a ho hanela timetso a bitsoa toughness ea tefiso.

Mojaro oa likarolo tse nang le tsoelo-pele e kholo o bitsoa charge array load.Matla, polasetiki le Angle tseo ho buuoeng ka tsona ka mor'a boima ba lipeipi tsa lisekoere tlas'a ts'ebetso ea lisebelisoa tsa lisebelisoa tsa tšepe kaofela ke litekanyo tsa ts'ebetso ea mochine tlas'a ketso ea mojaro o tsitsitseng oa Q215 welded square pipe.Ha e le hantle, mechine e mengata e tlas'a mosebetsi o boima khafetsa, tlas'a tikoloho ena monyetla oohle oa ho khathala.Fatigue Angle ke ho lekanya data ea tšepe e bonolo le e thata ea nale.Mokhoa o sa tloaelehang ka ho fetisisa oa ho lokisa Angle ka hare bophelong ba hona joale ke khatello ea Angle mokhoa, e leng ho sebelisa palo e itseng ea sebopeho sa hlooho ea khatello e tlas'a mojaro o itseng o hatelloa ka holimo ho lekiloeng Q215 welded square tube data surface, ho latela. ho khatello boemong ba ho fumana boleng ba Angle.Mekhoa e seng mekae e sebelisoang ke HB, HRA, HRB, HRC le HV.Angular plasticity e bua ka matla a data ea tšepe tlas'a mojaro, deformation ea polasetiki (deformation e sa feleng) ntle le tšenyo.Plastic Q215 welded square tube, non-standard seamless square tube tube ke sekoaelo se chitja sa extrusion molding.The seamless tube le lintlha weld ho bolela, ke sekwere hlooho tube mofuta (torque tube), moea oa mefuta e mengata ea thepa e khona ho etsa phala ea mokha (square torque tube), e mahareng ho tloha, hobaneng, tšebeliso efe. ke bohareng, palo e kholo ea batho ba fokolang Q215 welded lisekoere tube tšepe tube e le ba seng bakae, bakeng sa sebopeho lisekoere tube, whitewash square tube, meralo phala (square torque tube), joalo-joalo Square tube Selelekela Square tube mesebetsi.

Sebopeho sa Lik'hemik'hale

Lintho tse bonahalang tsa S460N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| boholo 0.2 | boholo 0.6 | 1 - 1.7 | boholo 0.8 | boholo 0.03 | boholo ba 0.025 | boholo 0.3 | boholo 0.1 | boholo 0.2 | boholo ba 0.025 | boholo 0.05 | boholo 0.05 | boholo 0.02 | boholo ba 0.55 | boholo ba 0.55 |

Lintho tse bonahalang tsa S420N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| boholo 0.2 | boholo 0.6 | 1 - 1.7 | boholo 0.8 | boholo 0.03 | boholo ba 0.025 | boholo 0.3 | boholo 0.1 | boholo 0.2 | boholo ba 0.025 | boholo 0.05 | boholo 0.05 | boholo 0.02 | boholo ba 0.55 | boholo ba 0.52 |

Lintho tse bonahalang tsa S420NL

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| boholo 0.2 | boholo 0.6 | 1 - 1.7 | boholo 0.8 | boholo ba 0.025 | boholo 0.02 | boholo 0.3 | boholo 0.1 | boholo 0.2 | boholo ba 0.025 | boholo 0.05 | boholo 0.05 | boholo 0.02 | boholo ba 0.55 | boholo ba 0.52 |

Lintho tse bonahalang tsa S460NL

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| boholo 0.2 | boholo 0.6 | 1 - 1.7 | boholo 0.8 | boholo ba 0.025 | boholo 0.02 | boholo 0.3 | boholo 0.1 | boholo 0.2 | boholo ba 0.025 | boholo 0.05 | boholo 0.05 | boholo 0.02 | boholo ba 0.55 | boholo ba 0.55 |

Thepa ea Mechini

Lintho tse bonahalang tsa S460N

| Botenya ba lebitso (mm): | ho ea ho 100 | 100 - 200 |

| Rm- Matla a tsitsitseng (MPa) | 540-720 | 530-710 |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100 - 150 | 150-200 |

| ReH- Bonyane matla a tlhahiso (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Matla a amang (J) bolelele., (+N) | +20 ° 55 | 0° 47 | -10° 43 | -20 ° 40 | |

| KV- Matla a amang (J) a fetelletseng, (+N) | +20 ° 31 | 0° 27 | -10° 24 | -20 ° 20 | |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ So (%) | 17 | 17 | 17 | 17 | 17 |

Lintho tse bonahalang tsa S420N:

| Botenya ba lebitso (mm): | ho ea ho 100 | 100 - 200 | 200 - 250 |

| Rm- Matla a tsitsitseng (MPa) | 520-680 | 500-650 | 500-650 |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100 - 150 | 150-200 | 200 - 250 |

| ReH- Bonyane matla a tlhahiso (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Matla a amang (J) bolelele., (+N) | +20 ° 55 | 0° 47 | -10° 43 | -20 ° 40 | |

| KV- Matla a amang (J) a fetelletseng, (+N) | +20 ° 31 | 0° 27 | -10° 24 | -20 ° 20 | |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200 - 250 |

| A- Min.elongation Lo = 5,65 √ So (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Lintho tse bonahalang tsa S420NL

| Botenya ba lebitso (mm): | ho ea ho 100 | 100 - 200 | 200 - 250 |

| Rm- Matla a tsitsitseng (MPa) | 520-680 | 500-650 | 500-650 |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100 - 150 | 150-200 | 200 - 250 |

| ReH- Bonyane matla a tlhahiso (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Matla a amang (J) bolelele., (+N) | +20 ° 63 | 0° 55 | -10° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Matla a amang (J) a fetelletseng, (+N) | +20 ° 40 | 0° 34 | -10° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200 - 250 |

| A- Min.elongation Lo = 5,65 √ So (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Lintho tse bonahalang tsa S460NL

| Botenya ba lebitso (mm): | ho ea ho 100 | 100 - 200 |

| Rm- Matla a tsitsitseng (MPa) | 540-720 | 530-710 |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100 - 150 | 150-200 |

| ReH- Bonyane matla a tlhahiso (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Matla a amang (J) bolelele., (+N) | +20 ° 63 | 0° 55 | -10° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Matla a amang (J) a fetelletseng, (+N) | +20 ° 40 | 0° 34 | -10° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Botenya ba lebitso (mm): | ho ea ho 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ So (%) | 17 | 17 | 17 | 17 | 17 |

Pontšo ea Sehlahisoa