TA2 titanium alloy tube bakeng sa tšebeliso ea indasteri

TA2 Titanium Alloy Pipe, Melemo

TA2 Titanium Alloy Pipe, Ha e bapisoa le lisebelisoa tse ling tsa tšepe, e na le melemo e latelang:

1. Matla a phahameng a khethehileng (matla a matla / boima) (bona setšoantšo), matla a matla a ka fihla ho 100 ~ 140kgf / mm2, ha boima bo le 60% feela ea tšepe.

2. Matla a mocheso a mahareng a lokile, mocheso oa tšebeliso o na le likhato tse makholo a 'maloa ho feta motsoako oa aluminium, mocheso o mahareng o ntse o ka boloka matla a hlokahalang, o ka sebetsa ka mocheso oa 450 ~ 500℃ nako e telele.

3. Ho hanyetsa ha kutu e ntle, holim'a titanium sepakapakeng hang-hang ho thehile lera la junifomo le filimi e teteaneng ea oxide, e na le bokhoni ba ho hanela mefuta e sa tšoaneng ea khoholeho ea mecha ea litaba.Titanium ka kakaretso e na le khanyetso e ntle ea kutu mecheng ea litaba ea oxidizing le e sa nke lehlakore, haholo metsing a leoatle, chlorine e metsi le litharollo tsa chloride.Empa ka ho fokotsa mahareng, joalo ka hydrochloric acid solution, titanium corrosion resistance ke e mpe.

4. Li-alloys tsa Titanium tse nang le ts'ebetso e ntle ea mocheso o tlase le likarolo tse tlase haholo tsa tumello, joalo ka TA7, li ka boloka polasetiki e itseng ho -253℃.

5. Modulus e tlaase ea elastic, conductivity e nyenyane ea mocheso, ha ho na ferromagnetism.

6. Boima bo phahameng.

7. Thepa e mpe ea setempe le thermoplasticity e ntle.

Phekolo ea mocheso Titanium alloy e ka fumana sebopeho se fapaneng sa mekhahlelo le sebopeho sa microstructure ka ho lokisa ts'ebetso ea kalafo ea mocheso.Ka kakaretso ho nkoa hore equiaxed microstructure e ntle e na le polasetiki e ntle, botsitso ba mocheso le matla a mokhathala.Sebopeho sa acicular se na le matla a phahameng a tšoarellang, matla a ho hahaba le ho thatafala ha fracture.Mehaho e tsoakaneng e leka-lekaneng le acicular e na le thepa e felletseng e felletseng.

TA2 Titanium Alloy Pipe, Mekhoa e sebelisoang hangata ea kalafo ea mocheso ke annealing, tharollo le kalafo ea botsofali.Annealing ke ho felisa khatello ea kelello ea ka hare, ho ntlafatsa polasetiki le botsitso ba microstructure, e le ho fumana thepa e feletseng e phethahetseng.Ka kakaretso, mocheso o kenang oa α alloy le (α+β) motsoako ke 120 ~ 200℃ ka tlas'a ntlha ea phetoho ea (α+β) -- → β phase.Tharollo le phekolo ea botsofali ke ho fumana α 'phase le metastable β phase ea martensite ka ho pholile ka potlako sebakeng sa mocheso o phahameng, ebe o senya mekhahlelo ena e tsitsitseng ka ho tšoara sebakeng sa mocheso o bohareng, le ho fumana likaroloana tse ntle tse qhalakaneng tsa bobeli. , joalo ka α phase kapa motsoako, ho finyella morero oa ho matlafatsa motsoako.Hangata (alpha + beta) motsoako oa ho tima ka alpha + beta) -- - > sebaka sa phetoho sa beta se ka tlase ho 40 ~ 100 ℃, metastable beta alloy quenching ka alpha + beta) -- - > sebaka sa phetoho ea beta ka holimo ho 40 ~ 80 ℃.Mocheso oa botsofali ka kakaretso ke 450 ~ 550 ℃.Ho phaella moo, e le ho finyella litlhoko tse khethehileng tsa workpiece, indasteri e boetse e sebelisa annealing habeli, isothermal annealing, β mocheso oa mocheso, deformation mocheso oa mocheso le ts'ebetso e meng ea phekolo ea mocheso oa tšepe.

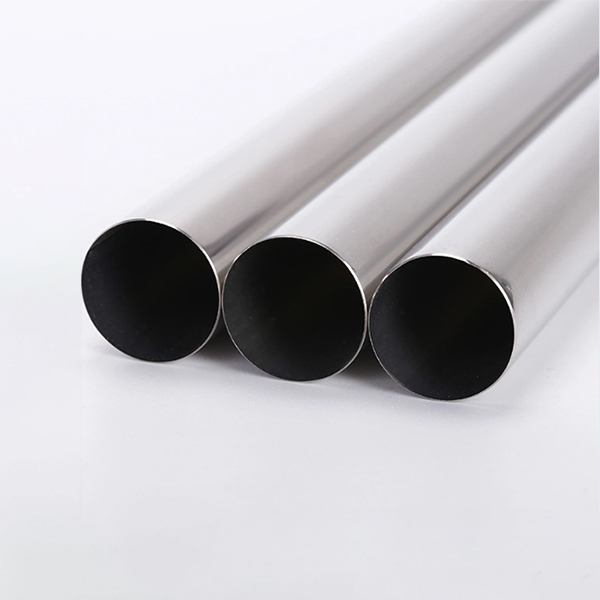

TA2 Titanium Alloy Pipe, Classification

Pipe ea titanium, peipi ea welding ea titanium, tee ea ho kopanya titanium, setsoe sa titanium splicing, ring ea titanium welding, ho fokotsa titanium, tee ea titanium, setsoe sa titanium, chimney ea titanium, joalo-joalo.

TA2 Titanium Alloy Pipe, Molao-motheo o sebetsang oa

TA2 Titanium Alloy Pipe, Haholo-holo e hokahanyang mefuta eohle ea liphaephe tsa lisebelisoa tsa titanium, tse sebelisetsoang ho potoloha thepa pakeng tsa mefuta eohle ea lisebelisoa, phala e na le ho hanyetsa ha kutu ea thepa ea titanium ka boeona, e le hore e nke sebaka sa phala e akaretsang bakeng sa phala e tloaelehileng e ke keng ea finyella tlhokahalo. .Ka kakaretso ф 108 ka holimo ke liphaephe tse cheselitsoeng.

Mekhahlelo ea mantlha ea tekheniki

| DN (mm) | Ho lekanya bophara ba kantle (mm) | Boitsebiso |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

Pontšo ea Sehlahisoa