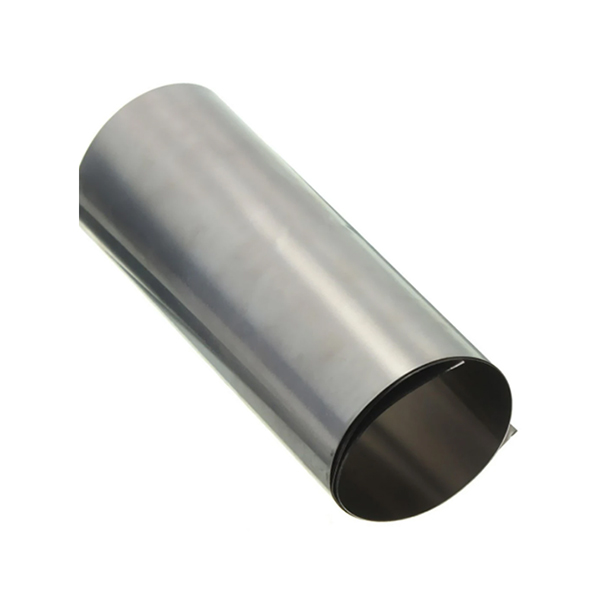

TC2 Titanium Alloy Aheet Plate

TC2 Titanium Alloy Aheet Plate, Alloy e thehiloeng ho titanium e nang le likarolo tse ling.Ho na le mefuta e 'meli ea likristale tsa homogenous ho titanium: α titanium e nang le sebopeho se teteaneng sa hexagonal e ka tlase ho 882 ℃, le β titanium e nang le khubu e bohareng ba 'mele e kaholimo ho 882 ℃.

Litlhoko tsa tekheniki:

1. Motsoako oa lik'hemik'hale oa titanium le titanium alloy plate o tla lumellana le litokisetso tsa GB/T 3620.

2. Tabeng ea ho hlahlojoa hape, ho kheloha ho lumelletsoeng ha motsoako oa lik'hemik'hale ho tla lumellana le litokisetso tsa GB/T 3620.

a.ho kheloha ho lumelletsoeng ha botenya ba poleiti ho lokela ho tsamaellana le lipehelo tsa Lethathamo la 1.

b.kheloha e lumelletsoeng ea bophara le bolelele ba poleiti e lokela ho tsamaellana le lipehelo tsa Lethathamo la 2.

c.likhutlo tsa poleiti li lokela ho khaoloa ka li-angles tse nepahetseng ka hohle kamoo ho ka khonehang.Ho kheloha ha hoa lokela ho feta bolelele le bophara ba lakane

TC2 Titanium Alloy Aheet Plate, Tlhaloso ea Tlhahiso

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30- 80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Plate, Boemo ba Tlhahiso

Sebaka sa ho sebetsa se chesang (R) Sebaka sa ho sebetsa se batang (Y) Sebaka sa ho sebetsa (M)

TC2 Titanium Alloy Aheet Plate, Reference Standard

1: GB 228 Metal tensile teko mokhoa

2: GB/T 3620.1 Titanium le titanium alloy limaraka le metsoako ea lik'hemik'hale

3: GB/T3620.2 Titanium le alloy ea titanium e entsoeng lihlahisoa tse entsoeng ka lik'hemik'hale le sebopeho se khelohileng

4: Mokhoa oa holim'a leoatle oa GB 4698 bakeng sa tlhahlobo ea lik'hemik'hale ea titanium, titanium le ferroalloys

TC2 Titanium Alloy Aheet Plate, Litlhoko tsa Tekheniki

1: Motsoako oa lik'hemik'hale oa titanium le poleiti ea alloy ea titanium e tla lumellana le litokisetso tsa GB/T 3620.1.Tabeng ea ho hlahlojoa hape, ho kheloha ho lumelletsoeng ha motsoako oa lik'hemik'hale ho tla lumellana le lipehelo tsa GB/T 3620.2.

2: Phapang e lumelletsoeng ea botenya ba poleiti e lokela ho lumellana le lipehelo tsa Lethathamo la 1.

3: Phapang e lumelletsoeng ea bophara ba poleiti le bolelele e lokela ho tsamaellana le lipehelo tsa Lethathamo la 2.

4: Likhutlo tsa poleiti li lokela ho khaoloa ka li-angles tse nepahetseng ka hohle kamoo ho ka khonehang.Ho kheloha ha hoa lokela ho feta bolelele le bophara ba lakane

Alloying

TC2 Titanium Alloy Aheet Plate, Alloy e thehiloeng ho titanium e nang le likarolo tse ling.Ho na le mefuta e 'meli ea likristale tsa homogenous ho titanium: α titanium e nang le sebopeho se teteaneng sa hexagonal e ka tlase ho 882 ℃, le β titanium e nang le khubu e bohareng ba 'mele e kaholimo ho 882 ℃.

(1) Lintho tsa alloying li ka aroloa ka mekhahlelo e meraro ho latela phello ea tsona ho mocheso oa phetoho ea mohato:

α -e tsitsitseng, tse kang aluminium, carbon, oksijene le naetrojene, ho tsitsisa karolo ea α le ho eketsa mocheso oa phetoho ea mohato.Aluminium ke karolo e ka sehloohong ea motsoako oa titanium alloy, e nang le phello e hlakileng ea ho ntlafatsa matla a motsoako mochesong oa kamore le mocheso o phahameng, ho fokotsa matla a khoheli le ho eketsa modulus ea elastic.

(2) β -stable elements e ka aroloa ka mefuta e 'meli: isocrystalline le eutectoid.Lihlahisoa tse entsoeng ka alloy ea titanium

Ea pele e na le molybdenum, niobium, vanadium joalo-joalo;Ea ho qetela e na le chromium, manganese, koporo, tšepe, silicon joalo-joalo.

(3) Lintho tse nang le phello e fokolang mochesong oa phetoho ea mohato ke likarolo tse sa nke lehlakore, tse kang zirconium le tin.

Oksijene, naetrojene, k'habone le hydrogen ke litšila tse ka sehloohong tsa li-alloys tsa titanium.Ho qhibiliha ha oksijene le naetrojene karolong ea α e kholoanyane, e nang le phello e matla ea ho matlafatsa motsoako oa titanium, empa e fokotsa polasetiki.Likahare tsa oksijene le naetrojene ho titanium hangata li ka tlase ho 0.15 ~ 0.2% le 0.04 ~ 0.05%, ka ho latellana.Hydrogen e na le ho qhibiliha ho fokolang haholo mokhahlelong oa α, 'me haedrojene e ngata haholo e qhibilihisitsoeng ka li-alloys tsa titanium e hlahisa li-hydrides, tse etsang hore alloy e brittle.Likahare tsa hydrogen ka har'a alloy ea titanium hangata li laoloa ka tlase ho 0.015%.Ho qhibiliha ha hydrogen ho titanium ho ka khutlisetsoa morao 'me ho ka tlosoa ka vacuum annealing.

Sebopeho sa Lik'hemik'hale

| Kereiti | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6,75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Matla a tšepe

| Kereiti | Elongation(%) | Matla a Tensile (Mits) | Yield Strength (Mits) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Lihlahisoa tsa Titanium le Alloy

| Lebitso la sehlahisoa | Litlhaloso |

| Titanium Rod & Bar & Ingots | Ф3mm~Ф1020mm, boima ba 'mele bo fihla ho 12t |

| Letlapa la Titanium | (80~400)mm×(~1500)mm×(~2600)mm |

| Lihlahisoa tsa Titanium | Boima ka sengoathoana≤2000kg |

| Lipoleiti tse chesang tsa Titanium | (4~100)mm×(800~2600)mm×(2000~12000)mm |

| Leqephe le kentsoeng ka Titanium | (0.01~4.0)mm×(800~1560)mm×(~6000) mm |

| Titanium foil / Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Lithapo tsa Titanium / Liphaephe | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

| Litekanyetso | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Sehlopha sa Titanium |

|

Pontšo ea Sehlahisoa